MANUFACTURING CAPABILITY

Manufacture of printed circuit boards

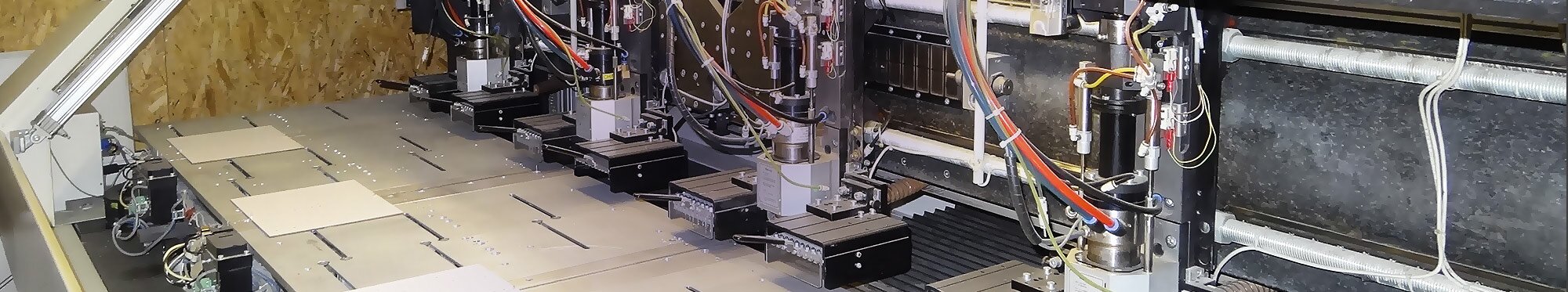

Our plant has a set of advanced imported equipment to manufacture printed circuit boards of accuracy class 1-5 according to GOST 23751-86.

Technical capabilities:

- Single sided printed boards

- Two-sided printed boards

- Aluminium-based boards

- Polyimide- and ceramic-based boards

Printed boards acid pickling

- copper foil thickness – 18 µm, 35 µm, 50 µm, 70 µm, 105 µm;;

- contour processing – milling and scribing;

- labelling – line thickness – 0.1-0.3 mm.

Printer board parameters:

- Minimum dimensions 5x5 mm

- Maximum dimensions 600x1000 mm

- Minimum conductor width and clearance in narrow areas 0,15/0,15 mm

- Minimum l contact area / minimum via diameter 1,0/0,3-0,1 mm.

Materials:

- foil-coated glass-fiber laminate - FR-4, СФ, СМ1, СМ3, СМ4, etc;

- aluminium laminate ACCL 1060, CS-AL 88, ACCL 5052.

Accuracy class according to GOST23751-86 up to Class 5 inclusive.

XV, RS protective soldering photomask Coating with protective soldering photomask with semi-automatic screen printing machine.

Top coat:

- galvanic ПОС61with fusion;

- ГорПОС 61;

Printed board contours and notches of any complexity.

Automated production of electronic circuit boards made it possible to significantly reduce the time of manufacture and save consumables. A former labyrinth of wires, the circuit is now replaced with one or two circuit boards. Service is now as simple as simply changing the microchip making the service less expensive. The electronic printed circuit board marked a new era of engineering and research with improved household utilities and equipment that became more ergonomic and light compared with their predecessors.

Printed circuit boards

Printed circuit boards We offer payment by instalments

We offer payment by instalments Printed circuit boards manufacturing

Printed circuit boards manufacturing We implement your ideas

We implement your ideas