After transferring the data to the circuit board the design engineer will examine the dimensions of the elements interconnected with electrical lines. The developer will replace these lines with a conductive pattern on the board’s base. Only an expert can calculate the best arrangement of the components and the minimum length of the conductive path. The conductive pattern’s elements, except conductors and contacts, screens and earth bus, are located at a minimum distance from the edge equal to the board’s thickness depending on the components sizes.

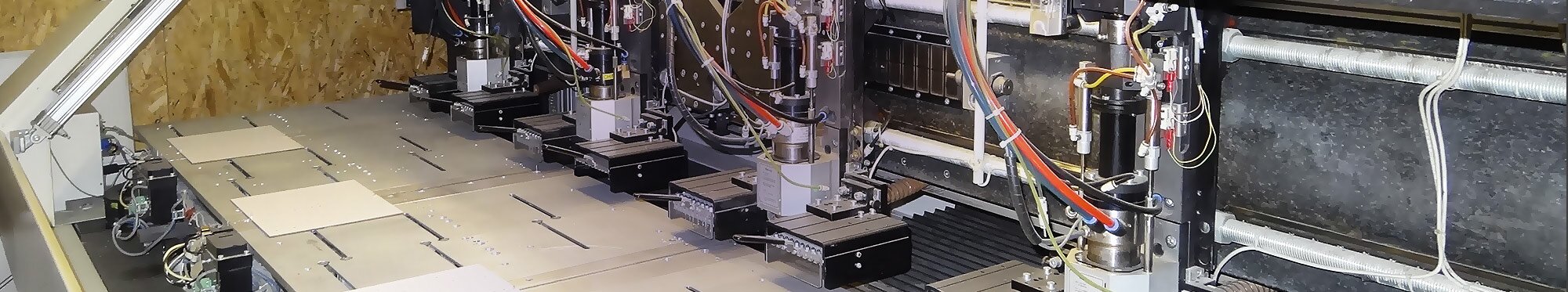

Single piece manufacture of custom printed circuit boards requires clear components specifications. It refers to the circuit element’s icon, the body’s dimensions and the lead identification, the component’s body type , the component’s installation width. The data groups have a detailed description of complex components made up of several elements. Each data group is named by the element type. The information can be stored in individual files or structured in databases. One file contains information on the two sides of the board, the holes arrangement and the board’s basic parameters. The data selected is transformed into an artwork for milling the circuit’s basis and drilling holes.

Printed circuit boards

Printed circuit boards We offer payment by instalments

We offer payment by instalments Printed circuit boards manufacturing

Printed circuit boards manufacturing We implement your ideas

We implement your ideas